Overview

Our UGM Test and Analysis Laboratory, which is an accredited laboratory, has started to provide GTIP determinations in raw materials, semi-finished and finished plastic and textile products with spectroscopic and microscopic analyzes since 2019, with its many years of experience in tariff determination; 2021 As of 2022, it has taken this one step further and started to provide services as a full-fledged laboratory, breaking new ground in its sector.

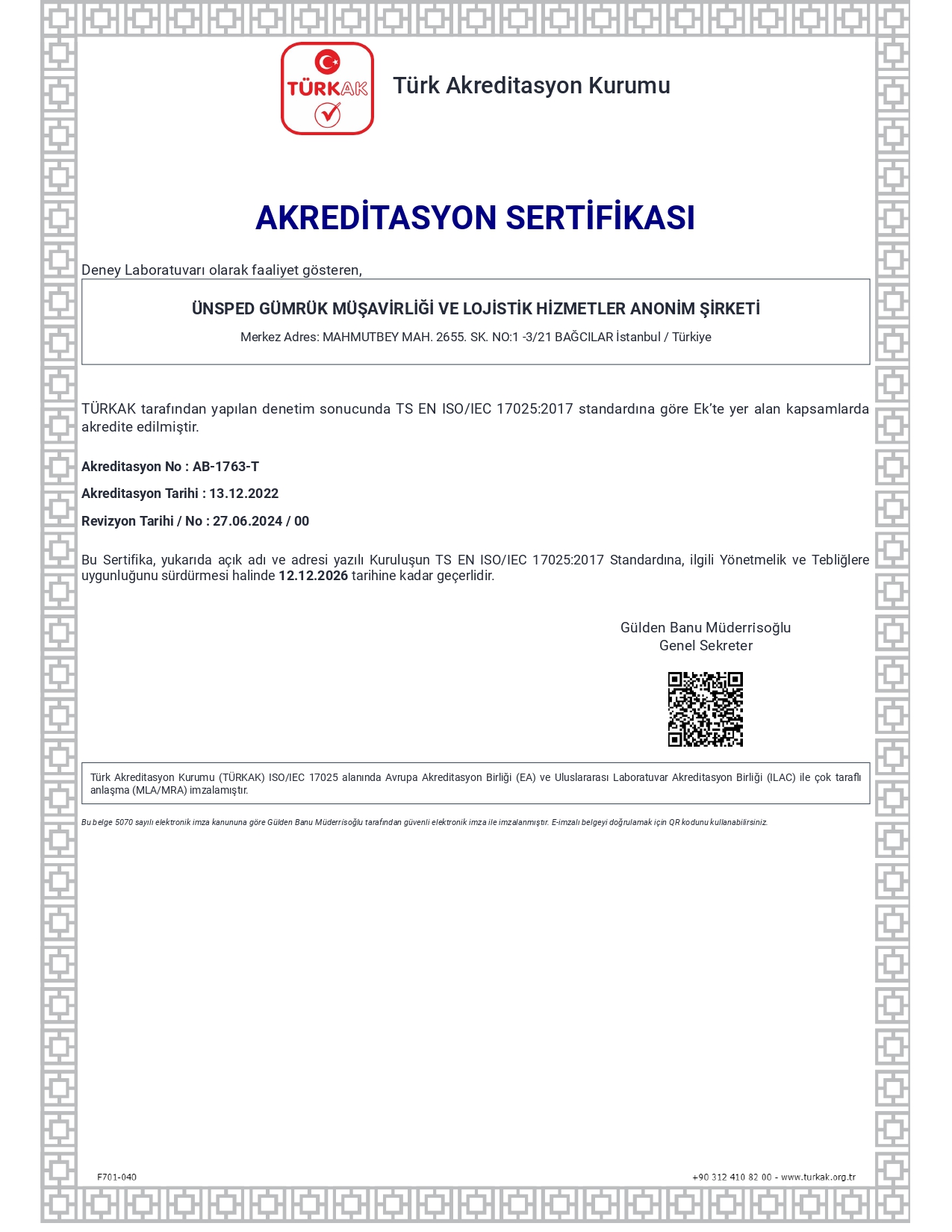

Our laboratory has met the general conditions for the qualification of test and calibration laboratories and has been certified to the international standard TS/A in 2022. It has been awarded the EN ISO17025 Accredited Laboratory certificate by the Turkish Accreditation Agency (TÜRKAK), the only authorized institution.

Our mission

To provide professional service to our customers with good professional and technical practices, to continuously ensure quality and efficiency in testing and/or analysis services;

All its work is carried out in accordance with TS EN ISO/IEC 17025 standard To carry out and develop and improve the quality management system in line with the requirements of service quality;

To meet the testing and/or analysis needs at the maximum level and on time, using national and international standards or in line with applicable customer conditions.

Our vision

Ensuring the participation of all employees in quality improvement studies with the total quality management approach;

Expanding the scope of service determined in line with customer needs to constantly meet customer demands;

Employees To ensure their development through continuous training according to developing technological conditions.

Our target

To ensure that all personnel work in line with the management system targets, to ensure their joint participation to achieve the targets, and to reach a level of awareness that can evaluate the impact of their work on achieving the targets;

To ensure that the laboratory personnel effectively implement the quality management system To ensure that they work in accordance with the established quality system by organizing the necessary information and awareness meetings;

Avoiding activities that harm the environment in all their work.

Our principle

Stay established in accordance with the conditions of TS EN ISO/IEC 17025 standard To ensure the continuity, continuous improvement and effectiveness of the management system;

To adhere to the principles of impartiality, accuracy and confidentiality in testing and/or analysis services.

OUR ANALYSIS SERVICES

A total of six expert chemists, two of whom have doctoral degrees, work within the UGM Test and Analysis Laboratory. Almost all of our chemists are experts who previously worked in the Customs Laboratory of the Ministry of Commerce.

UGM Test and Analysis The purpose of the laboratory is to analyze the products before the declaration registration and determine their tariff positions accurately; thus, to provide cost and time advantages to the companies by preventing possible financial risks and penal situations that may arise by ensuring that the GTIP declaration is made without errors. The analyzes carried out within the company are listed below:

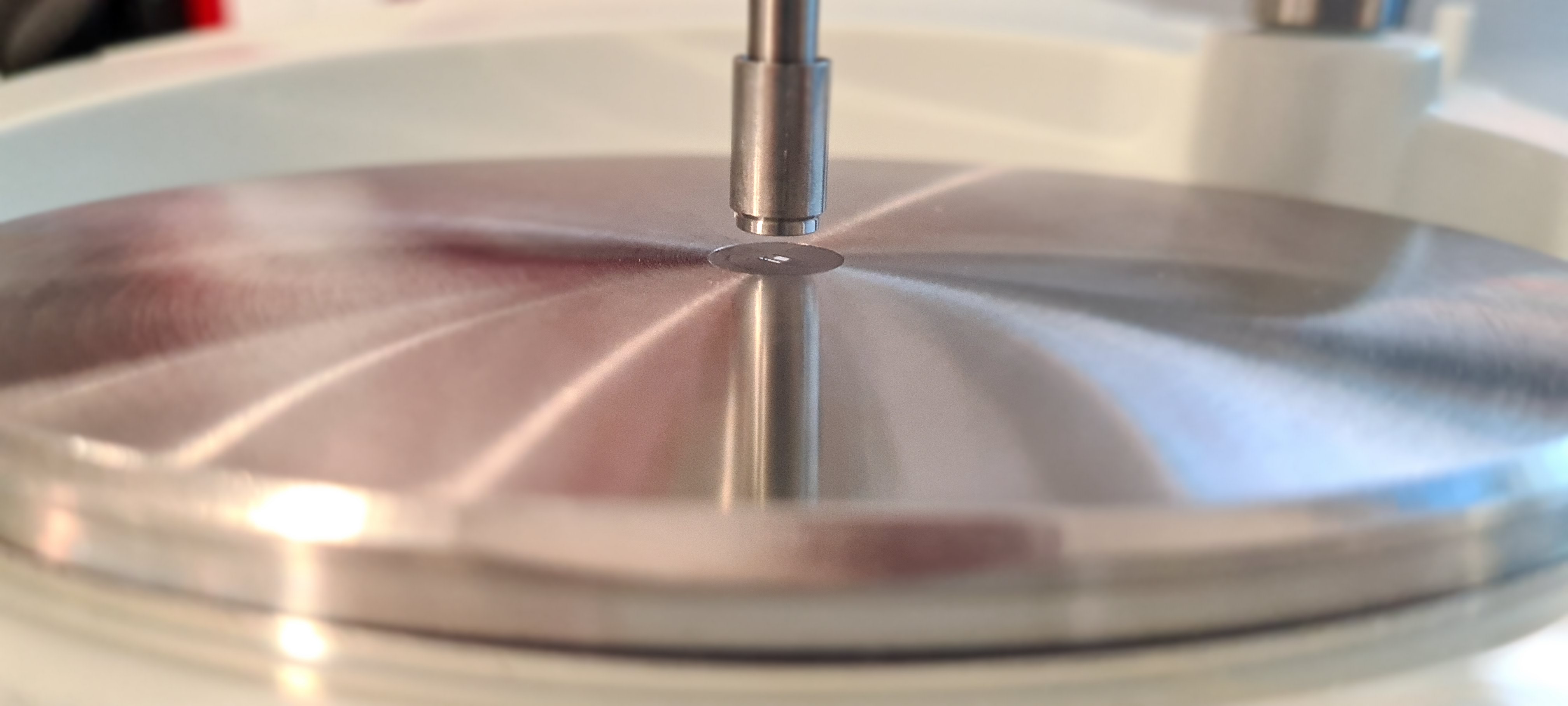

FT-IR Spectroscopic Analysis

With the FT-IR Spectroscopy method, the characterization of polymeric materials from which plastics are made can be made.

Examples of these are polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), PTFE. fluorinated polymers, polyamide (PA) and polyesters (PES) can be given.

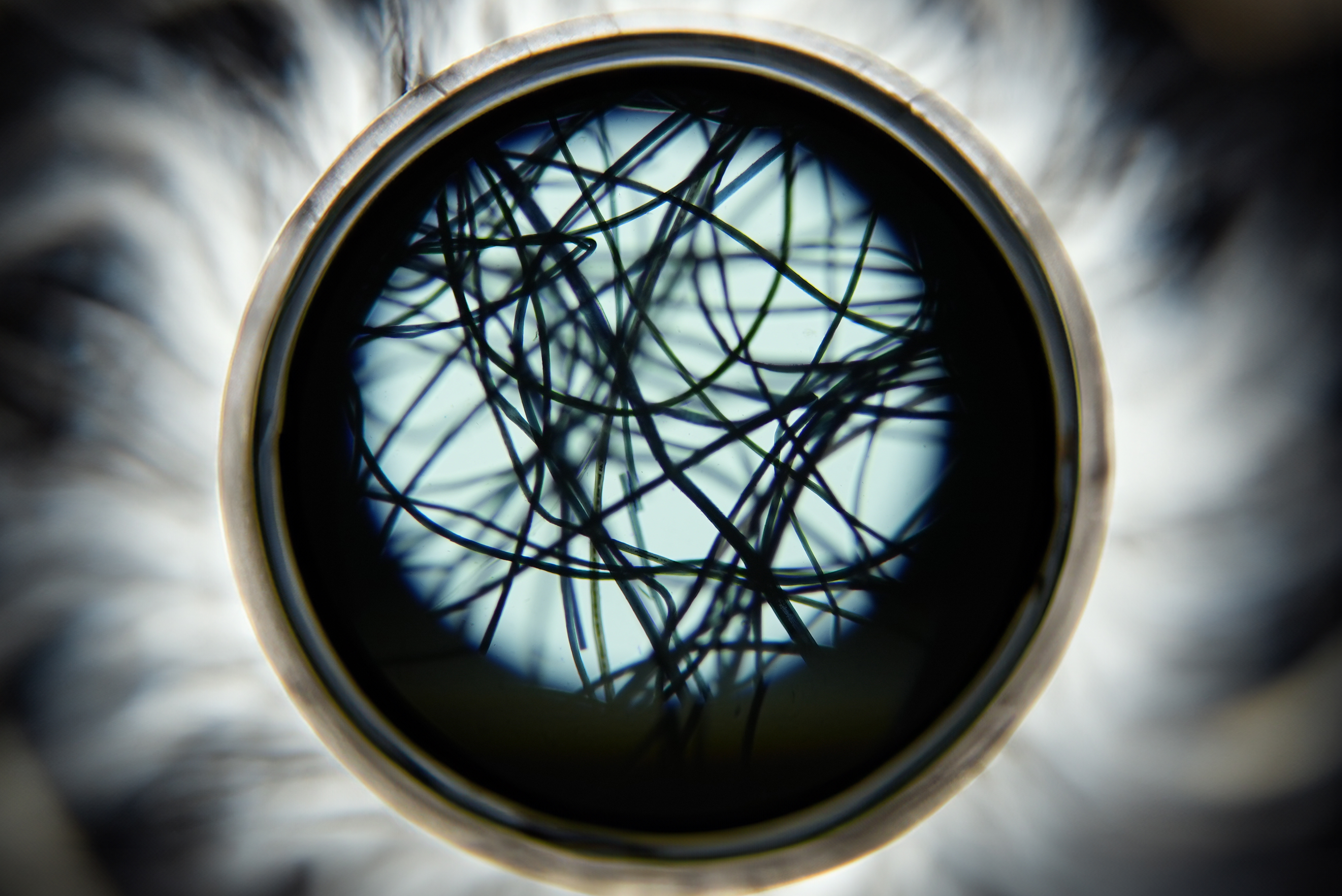

Qualitative Fiber Analysis

Qualitative Fiber Analysis is the separation of textile fibers under a microscope. Examining the structures of textile fibers under a microscope is important for a closer recognition of the fibers. This analysis method is a microscopic analysis to understand which fibers the woven, knitted or non-woven fabrics or yarns are made of. In this way, the surface enlarged to the desired size under the microscope is examined in detail and, if necessary, recorded digitally.

Quantitative Fiber Analysis

Quantitative Fiber Analysis is the determination of fiber ratios in textile fibers. This analysis is the process of performing quantitative chemical analysis of fabrics consisting of a double and triple fiber mixture (blend). The basic principle in chemical quantitative fiber analysis is; the fibers that make up the fiber mixture It is the chemical analysis of the mixture sample with a suitable solvent that dissolves one but not the other, by weighing the remaining part and calculating the ratio according to the initial sample amount and thus determining the proportions of the fibers in the mixture.

Chemical Analysis

With the chemical analysis method, analysis and solubility tests of surfactant chemicals such as soaps, detergents, etc. can be performed.

GBF(SDS) SERVICE

WHAT IS SDS?

MSDS, known in Turkish as Safety Data Sheet (SDS), is a document that provides information about health, safety and environmental risks related to the safe use of chemical substances. SDS This document contains the dangers of the chemical substance, precautions regarding its use, emergency scenarios and the legislation to be followed. In Turkey, MSDS is issued under the KKDIK legislation as GBF. It is prepared in accordance with international standards.

SDS SCOPE AND PREPARATION AUTHORITY

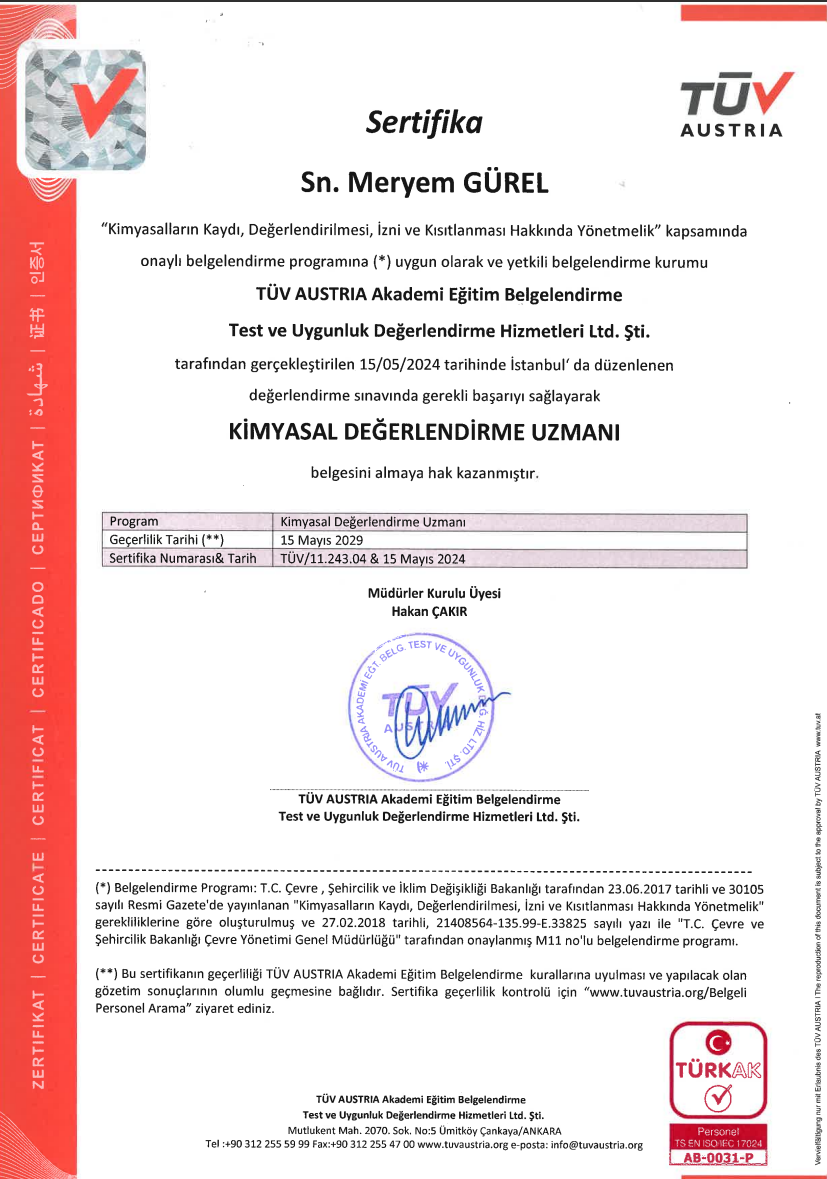

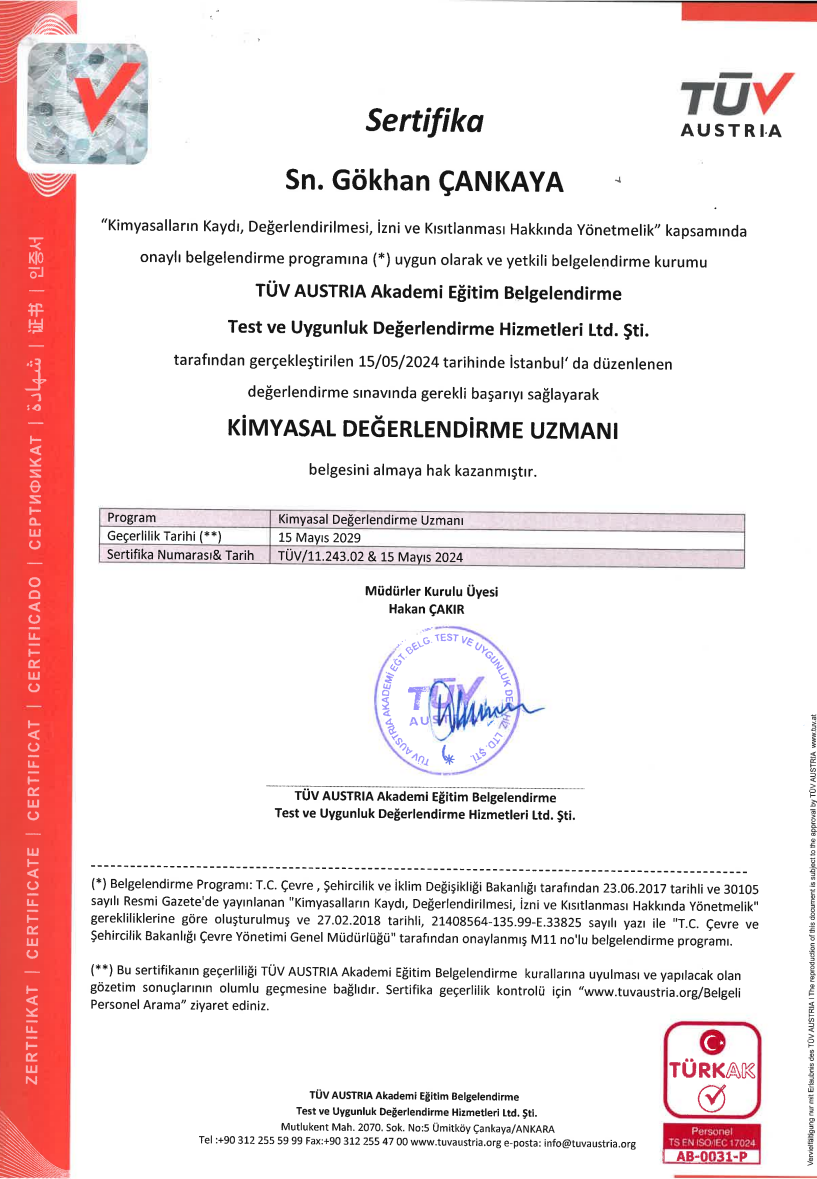

Safety Data Sheet is a document that is mandatory for hazardous chemicals and products. The Safety Data Sheet is prepared in Turkish by the businesses that distribute or use it, in accordance with KKDİK Annex-2 and by a chemical evaluation expert certified in accordance with Annex-18.

SDS in UGM

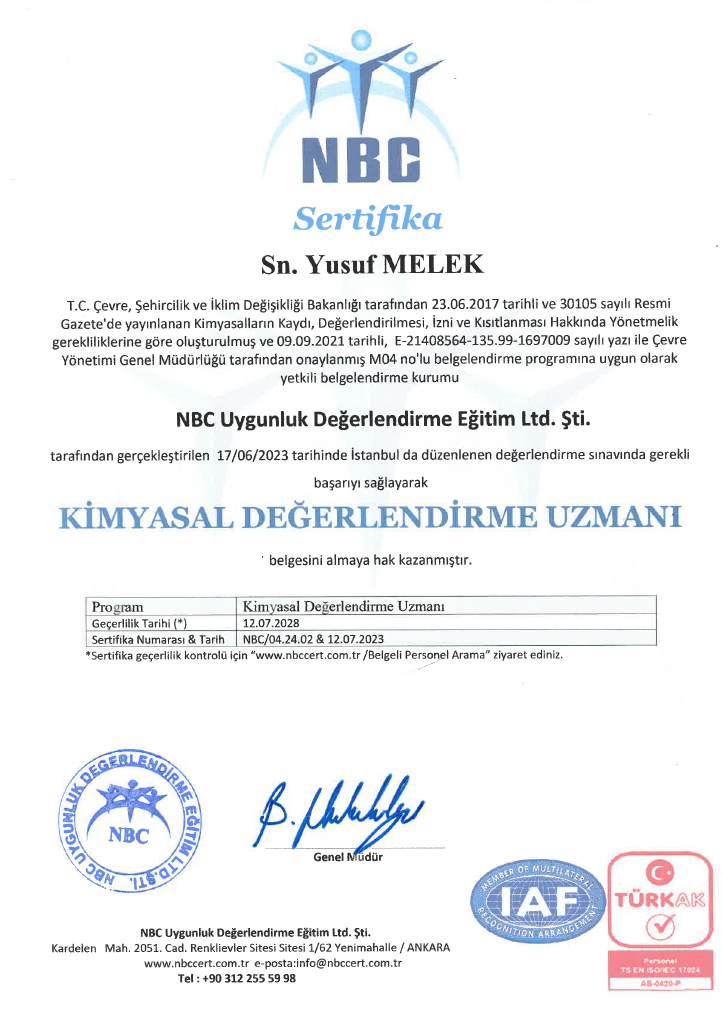

Ünsped Gümrük Müşavirliği ve Logistics Services Inc. has been providing Security Information Form preparation services as of July 2023. MSDSs are prepared by Chemical Evaluation Specialist Yusuf Melek, a graduate of Boğaziçi University Department of Chemistry. MSDS Delivery time is maximum 3 business days. Depending on demand, requests can be answered on the same day or the next business day.

Geri

Geri